What Can Go Wrong?

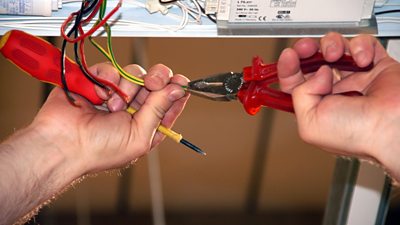

Electricity creates many potential hazards, some common ones are as follows:

- Fires can occur if electrical equipment (including wiring) develops a fault or circuits are overloaded

- Contact with electricity can cause electrical shock and/or burns

- Faults with mains electrical systems can develop a tremendous amount of energy in a short time - so much so that it actually causes explosions

- Electrical protection devices can be rendered useless by long cables or the wrong equipment

- Using electrical equipment in higher risk environments: wet, damp, humid, dusty conditions, increases the hazards significantly

- Fires and burns from contact with hot surfaces

- Batteries can start and sustain fires if the terminals are shorted together

- Electrical circuit protection may not work properly if the electrical system is not properly designed

- Earthing systems need to be effective and co-ordinated if there are multiple contractors or electrical supplies (e.g. generators)

- Some electrical problems (e.g. poor design) may only become apparent when there is a fault and the protection against shock or fire doesnβt work

Legal/ΒιΆΉΤΌΕΔ Requirements

- All electrical systems have to comply with the Electricity at Work Regulations 1989. This places requirements on dutyholders to ensure that electrical systems are designed managed and maintained by those with sufficient skills, knowledge and experience

- The ΒιΆΉΤΌΕΔ expects all temporary electrical systems to comply with the IET Wiring Regulations (BS 7671) β often known as βThe 18th Editionβ or βWiring Regsβ

- Temporary electrical systems, no matter how small, also need to comply with BS 7909, a code of practice for temporary electrical systems published by BSI

General Requirements

- Use a ΒιΆΉΤΌΕΔ pre-vetted contractor for dry or wet hire if in UK or, if not possible, discuss with ΒιΆΉΤΌΕΔ Procurement and ΒιΆΉΤΌΕΔ SSR before progressing

- Ensure those working with electrical systems are competent to do so. See ΒιΆΉΤΌΕΔ Guidance on assessing competence for electrical work. Competence is relative to the work undertaken β for example a lighting cameraman with two lights may, after suitable instruction, be competent to specify and check the system. A higher degree of electrical knowledge and skill is required for complex systems such as those using generators for example

- All temporary electrical systems must be erected in safe manner and tested. Productions should appoint someone to ensure that this is carried out. This person is called the βSenior Person Responsibleβ (SPR) in BS 7909

- Large or complex systems must always have an electrical completion certificate and list of tests results completed. A copy of this is the evidence a production may need to demonstrate that electrical safety has been managed. Always request it from those deploying temporary electrical systems

- It is critical that electrical systems are looked at holistically, not just as kits of tested parts. It is possible to plug safe equipment together in an unsafe fashion

- Lighting is not the only department using power. The obligation extends to all those using or supplying electrical equipment in whatever quantity or scale

- Do not leave systems unattended when powered up unless suitable measures have been put in place to isolate the system in the event of a problem

BS 7909 β Small and simple systems under 6kW

The intent of this category is to simplify management of electrical safety based on the principles that electrical equipment is safe already (i.e. undergone recent portable appliance testing) and simple user checks are conducted. The key aspect is that systems are simple in design, usually derive power from ordinary domestic style sockets installed in the building and a protective device called a Residual Current Device (RCD) is used for additional protection against electric shock. Examples could be interviews, press launches, small drama shoots or editing work.

- The person in charge should decide if the system is small or more complex using the flowchart

- All equipment must come from a pre-vetted supplier and should be checked for electrical safety prior to being used (i.e. βPATβ tested)

- The person looking after the small system should have undergone the ΒιΆΉΤΌΕΔ Academy online training

- Systems need to be checked using a small plug-in style tester, and RCDs checked using the βTβ button

- If required the small/simple systems certificate should be completed

BS 7909 β Large or complex systems over 6kW

If it doesnβt fall into the small or simple category, it is large or complex. Examples of situations that may be small but not simple could be where power is obtained from generators; power is taken from a building and used outdoors; situations where there are other risks such as working on or near water, the event is in a venue where the electrical system is old or potentially unsafe and so on. For more guidance see pages on assessing electrical risks.

- Someone should plan the electrical system and co-ordinate suppliers as necessary. This may be the nominated Senior Person Responsible (SPR), the Producer or Production Manager for example. Considerations include where power is being taken from, cable routes and sizes, protective measures (earthing, RCDs or circuit breakers for example), facilities and crewing, testing and certification etc

- Occasionally, a specialist company may be required to produce a suitable design

- All final circuits must be protected by a 30mA Residual Current Device (RCD)

- The installation of fixing wiring and electrical equipment to scenery must be carried out by a competent electrician and certified in accordance with BS 7671, not BS 7909

- RCDs should never be taken out of circuit (bypassed or disabled) as they are safety devices. In a properly designed system they should not operate unless there is a fault, so there should be no need to remove the protection they afford

- Consider lightning and other adverse weather

Facilities and unit bases

Facilities and unit bases are situations where electrical safety is often poorly managed. All facility vehicles or trailers with installed electrical systems must have a valid or current Electrical Installation Condition Report (EICR) or certificate issued by a competent electrician on a frequency determined by the duty holder for the unit. This should be requested by the production prior to arriving on location.

- A visual inspection should be carried out on the connecting cable and all plugs and sockets-outlets before each and every transported use of the unit

- All portable electrical kit on board must be routinely checked (i.e. βPATβ tested) at a frequency determined by the owner or duty holder based on risk

- The person responsible for the facilities e.g., supervisor, chef/driver, make-up artist etc., must have a basic knowledge and understanding of the electrical system

- Generators must be effectively earthed and have RCD protection on the output. Earth spikes under wheels or dumped on the grass are not effective (see webpage on Generators)

Control Measures

- The dangers that electricity can create will, under most foreseeable situations, be removed or reduced to an acceptable level by following BS 7671 and BS 7909

- Select competent people to carry out electrical work. See separate ΒιΆΉΤΌΕΔ guidance on assessing competence in respect of electrical work

- It is important electrical systems are managed, such as by appointing a competent person to manage electrical infrastructure (i.e. the βSenior Person Responsibleβ or SPR)

- Consider additional or unusual risks associated with the deployment of the electrical system, such as rigging equipment at height, working in hot locations, near water or using supplies in other countries (see also guidance on assessing electrical risks)

- Visual checks should be made by all staff of the equipment, cables, sockets and location before connecting to any power source

- In the event of an emergency, it should be possible to easily isolate all electrical supplies

- Correct equipment should be selected for the job e.g. weatherproof connectors and distribution for outside use

- Obtain copies of the BS7671 Electrical Installation Certification for any fixed host power installation being used, if applicable

- Be aware of location of local isolating breaker switches and safety arrangements

- All cables to be appropriately routed and/or protected to reduce trip hazard and secure lamps & stands to avoid movement. Rubber mats do not provide mechanical protection for cables, they only reduce the trip hazard. Cables routed across access/egress routes should be in proper cable ramps

- Excess electric cable should not be left coiled as this can lead to overheating in the cable

- Consider members of the public when cabling and siting equipment, particularly ones who may have mobility or sight impairment

- Metal structural elements may need protective bonding to the electrical earthing arrangements. In most studios with painted floors or wooden rostra this is likely to be unnecessary. It is important to realise that putting protective bonding on structures that donβt need it could introduce a risk that wouldnβt otherwise be there

- There are extra requirements for generators, see the guidelines for generators

Non-ΒιΆΉΤΌΕΔ equipment including musical instruments

- Performers, make-up artists, musicians or similar have the same duties to ensure their electrical appliances are safe to use. Their equipment should have evidence of portable appliance testing such as a PAT label. Further guidance in this area is available from HSE guidance document INDG247

- Check that equipment from foreign suppliers is safe to use on UK supplies and voltages

- All equipment should be supplied via an RCD or, where not possible, a safety isolating transformer under the control of an electrically skilled person

- If equipment is, or is suspected to be unsafe, it should not be used

FAQs/Did You Know?

- Excessively long extension leads (particularly those daisy-chained together) can stop safety devices such as circuit breakers and fuses from working.

- Around 95% of electrical faults or damage can be found just by looking (visual inspection)

- Battery powered appliances reduce the risks associated with electricity significantly, but donβt remove them completely

- Although the risk of electric shock from battery powered devices is generally low, batteries (particularly modern lithium ones) can store a lot of energy When the terminals are shorted, the battery damaged or disposed of inappropriately or charged badly, that energy can start and sustain fires, even without oxygen. Typical fire extinguishers may not provide any help, other than to stop the fire spreading

- The ΒιΆΉΤΌΕΔ has revised it guidance for checking portable electrical appliances β see safety of electrical equipment

Division Specific Issues

No division specific issues

Useful documents

Recommended links

-

Certificate in Temporary Electrical Systems Electrical safety training course designed to ensure those working with electricity in temporary distribution systems on productions can comply with BS 7909

ΒιΆΉΤΌΕΔ electrical safety topics

-

Electrical safety homepage

A selection of guidance documents and general advice in relation to Electrical Safety in ΒιΆΉΤΌΕΔ premises, on productions and events. -

ΒιΆΉΤΌΕΔ policies for electrical safety

ΒιΆΉΤΌΕΔ policies detailing its overarching approach to the management of electrical safety. -

ΒιΆΉΤΌΕΔ electrical safety guidance documents

Summary of ΒιΆΉΤΌΕΔ electrical guidance (links within document titles) -

Electrical risk assessments and reporting of incidents

This section will help those who need to do a risk assessment where electricity is being used. It also gives guidance on reporting requirements for any electrically-related incident. -

Electrical safety in ΒιΆΉΤΌΕΔ Premises

General guidance on use of electricity and electrical equipment when working in ΒιΆΉΤΌΕΔ Premises. -

Electrical safety in Studios

A straightforward guide to electrical safety management in studios and similar locations. -

Safety of electrical equipment and appliances

Requirements for electrical safety of electrical equipment and appliances (βPAT testingβ). -

Electrical competency and Part P requirements

Guidance on what to look for when employing contractors or freelancers to do electrical work. -

Electrical safety requirements for Production Managers

Find out what you should know and what measures should be put in place for your production. -

Bringing your own equipment to work and contributorβs equipment

Basic guidance on the safe and appropriate use of personal electrical equipment whilst at work and requirements. -

Temporary electrical systems and BS 7909

Requirements for electrical safety management in accordance with BS 7909 for all temporary electrical systems. -

Small and Simple Temporary Electrical Systems

Guidance to help understand the requirements for simple temporary electrical systems such as interviews or photo shoots for example. -

Generators

Guidance on the use of temporary generators including the application of earth electrodes. -

Batteries

Guidance on the safe use and storage of batteries. -

Certificate in Temporary Electrical Systems

An electrical safety training course designed to ensure those working with electricity in temporary distribution systems on productions can comply with BS 7909 and the relevant parts of BS 7671. -

Electrical Principles Workshop to harmonise the approach to health and safety management on electricity across all areas.

Electrical Principles Workshop to harmonise the approach to health and safety management on electricity across all areas. -

External information and guidance on electrical safety

Links providing further information on all aspects of electrical safety, from external bodies (IET, HSE, Etc.) that ΒιΆΉΤΌΕΔ staff may find useful. Some guidance is required to be purchased. -

Health & safety Alerts and News

All the Health & Safety Alerts and News from the H&S Teams

More from SSR

-

Your platform to record accidents, risk assessments, assurance monitoring and inspections

-

Safety Equipment Stores

Just one number to call: 0844 800 8875 -

ΒιΆΉΤΌΕΔ Safety Guidelines

An A-Z of ΒιΆΉΤΌΕΔ's Health and Safety Guidelines -

Safety Advice Line: 0370 411 0464 Email: safety@bbc.co.uk

- A-Z of ΒιΆΉΤΌΕΔ Safety Guidelines

- Accident Reporting and Investigation

- ΒιΆΉΤΌΕΔ Health & Safety Policy

- Contractors (incl. vetted lists)

- Contributors

- Fire Safety

- Freelancers

- Independent Production Companies

- Risk Assessment

- Safety Alerts

- Safety Responsibilities

- Safety Training

- Sets & Premises Safety Guide

Events guidance - key links:

- Exhibitions

- General Guidance

- Indoor Location Recce Checklist

- Outdoor Location Recce Checklist

- Major Incidents & Emergency Planning

- Marketing and Promotional

- Noise Exposure

- Planning and Management

- Responsibilities

- Responsibilities Form

- Laser Lighting Effects

- Strobe Lighting

- Temporary Stages and Rostra

Health topics - key links:

- (ΒιΆΉΤΌΕΔ network only)

- Contributors Fitness to Participate

- Display Screen Equipment (DSE)

- (ΒιΆΉΤΌΕΔ network only)

- First Aid and Welfare on Location

- International Travel - Risks & Health

- Manual Handling

- Mental Health: ΒιΆΉΤΌΕΔpage

- (ΒιΆΉΤΌΕΔ network only)

- Personal Health and Wellbeing

- Pregnancy

- Psychological Trauma Support & Trauma Risk Management (TRiM)

- Tiredness and Fatigue

- Travel Health Contacts

ΒιΆΉΤΌΕΔ High Risk - key links:

- CBRN and Industrial Spills

- Covert Filming

- Crisis Management and Security Support

- Demonstrations, Protests and Crowds

- Disaster Coverage

- Door Stepping

- (ΒιΆΉΤΌΕΔ network only)

- (ΒιΆΉΤΌΕΔ network only)

- Public Order

- Safety Equipment Stores

ΒιΆΉΤΌΕΔ Journalism - key links:

ΒιΆΉΤΌΕΔ Productions - key links:

- Aerial Filming and Airfields

- Animals: Displaying and handling for performance

- Boats: Working on

- Children and Young People

- Driving

- Electrical Equipment and Systems

- First Aid and Welfare on Location

- Food Safety (Cooking and Catering)

- Remote Location Working

- Roads and Streets: Working by

- Security of Productions on Location

- Stunts

- Tiredness and Fatigue

- Unmanned Aerial Systems (UAS aka Drones)

- Vehicles: Recording in, from and around

- Working at Height: Mobile Elevating Work Platforms

- Working at Height: Tower Scaffolds

ΒιΆΉΤΌΕΔ Radio - key links:

- (ΒιΆΉΤΌΕΔ Network only)

ΒιΆΉΤΌΕΔ Security - key links:

ΒιΆΉΤΌΕΔ Sport - key links:

About this site

This site describes what the ΒιΆΉΤΌΕΔ does in relation to managing its health, safety and security risks and is intended for those who work directly for the ΒιΆΉΤΌΕΔ.

It is not intended to provide instruction or guidance on how third parties should manage their risks. The ΒιΆΉΤΌΕΔ cannot be held liable for how this information is interpreted or used by third parties, nor provide any assurance that adopting it would provide any measure of legal compliance. More information

Some links on this site are only accessible when connected to the ΒιΆΉΤΌΕΔ network