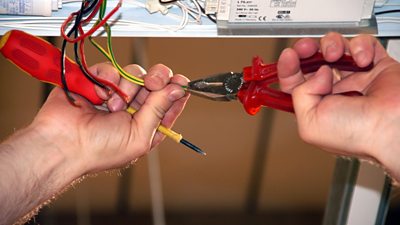

Electricity is a potent source of energy that can (and does) kill, injure and start fires. Fires in the UK where electricity was believed to be the cause number in the region of 20,000 per year. It is a significant, and foreseeable, hazard in the workplace.

Generally the risks are mitigated to an acceptable level in properly designed systems and will usually only manifest themselves if the electrical system is damaged or poorly designed. Given that most common electrical hazards can be seen by those with even the most elementary training, visual inspections and regular checks are a key aspect of all electrical safety plans.

What Can Go Wrong?

The main hazards of working with electricity are:

- shock by contact with a live or charged conductor

- burns from contact with or proximity to a live or charged conductor, by exposure to a high-energy discharge or arc

- fires and explosions caused by the ignition of flammable substances and materials by electricity

- explosions caused by the rupture of equipment subjected to excess or large fault currents

- interruption to essential safety equipment by loss of electrical power

- Electric shocks can also lead to other types of injury, for example by causing a fall from ladders or scaffolds etc

The Electricity at Work Regulations 1989 requires that the use of electricity be assessed for risk, not the electricity itself β which is known to be potentially dangerous. When conducting risk assessments around the use of electricity the following list may help:

- Are those doing electrical work competent to do so? Poorly designed or maintained systems may not provide effective protection

- Are you working near water, or is the system likely to be exposed to water or other liquids? Conductive liquids can make otherwise safe equipment live and pose a shock risk. There is guidance in standards (such as BS 7671) on what extra control measures to take

- Are animals involved? Because of their size and contact with ground, animals can be more susceptible to electric shocks

- Are you working in a hazardous location? E.g. filming in a mine, quarry or factory where explosive gases or dusts may be present

- Are there any overhead lines near where you are working? There are requirements for exclusion distances

- Do you plan to disturb the ground? This could be digging slit trenches to bury cables or putting up marquees or similar and hammering in spikes to the ground

- Do you plan to use generators or multiple supplies from different sources? If so consideration needs to be given to co-ordinating the earthing arrangements

- If you are doing an outdoor event, have you considered the safety and resilience of the electrical system in bad weather, particularly thunderstorms?

- Are uninterruptible power supplies (UPS) or multiple generators being used? If so these can remain live when the power supply is isolated so people need to be aware that isolating the supply may not isolate the system

- Will the electrical work involve other hazards? Examples include:

- Working at height

- Working near unprotected edges

- Work in confined spaces

- Exposure to animal waste (e.g. pigeon or rat effluent) when running temporary cables through roof spaces, building voids, seating terraces etc.

- Exposure to asbestos in unknown buildings

- Work on or near old electrical equipment in buildings

- Is any unusual or old electrical machinery being used that might need specific training or assessment? Examples could include stage automation or old lighting equipment

- Are multiple contractors involved in the work, such as a drama shoot or festival? If so the ΒιΆΉΤΌΕΔ has duties to ensure the workplace is kept electrically safe and this will probably require an element of co-ordination between contractors regarding the supply and checking of the electrical distribution

- Are you working abroad? The electrical systems and standards may be different to the UK and other local requirements might need to be met.

Legal/ΒιΆΉΤΌΕΔ Requirements

- The Electricity at Work Regulations 1989 (EAWR) requires those working with, on or near electrical systems to have sufficient competence to do so

- Requirements for the ΒιΆΉΤΌΕΔ are given in the document ΒιΆΉΤΌΕΔ Guidance on electrical competencies (see useful documents)

- The ΒιΆΉΤΌΕΔ expects all electrical systems to be design and erected in accordance with BS 7671, the IET Wiring Regulations. Temporary systems should also comply with BS 7909, Code of Practice for temporary electrical systems and related purposes

- All electrical accidents and near misses must be reported via MyRisks. Examples include damaged electrical equipment that presents an electrical hazard (e.g. exposed conductors, broken casing), any electric shocks, equipment that shows signs of overheating, fires or damage to installed equipment (e.g. socket-outlets, light fittings)

- A RIDDOR report only needs to be filed for any electric shock that comes under the usual injury reporting rules, namely:

- Results in the person having more than seven days of work

- The person is a member of the public and was taken to hospital for treatment

- The person loses consciousness at any point caused by a head injury or suffocation (e.g. person falls from height or suffers breathing difficulties following an electric shock)

- The person dies or suffers a specified injury (such as burns arising from the electricity)

- A RIDDOR report is also required for a dangerous occurrence, particularly:Employees must not do any electrical work if they have not had appropriate training or approval from their line manager

- Any plant or equipment coming into contact with an uninsulated overhead line or coming close enough that it caused an electrical discharge. If reported via RIDDOR such instances do not need to be reported under the requirements of the Electricity, Safety, Quality and Continuity Regulations

- Any explosion or fire caused by an electrical short circuit or overload (including those resulting from accidental damage to the electrical equipment) which either results in stoppage for more than 24 hours or causes a significant risk of death (e.g. a fire requiring intervention by the fire brigade). Note that an incident is reportable even if the system in which the damaged equipment was installed is put back into service using new equipment within 24 hours. In such a case an assessment should be made of how long a repair to the damaged equipment would have taken had it been attempted.

Control Measures

- Ensure all electrical systems are designed and erected by people with sufficient competence for the work in hand. That could be simple instruction for staff in offices, camera operators or sound engineers for example through to qualified electricians for installations or temporary systems. See ΒιΆΉΤΌΕΔ guidance on assessing competencies for more information

- The most common method of electrical protection in the UK is called Automatic Disconnection of Supply, which is achieved using circuit breakers, fuses and RCDs. It is important that when a system is put into service it has been tested to ensure that the devices will work. The results should be recorded on a test certificate.

- Generally all sockets that power equipment which will be handled or touched in use must be protected by an RCD which provides extra protection against electric shock

- Make sure all equipment is in good order and designed for the job

- Ensure installations are inspected and tested regularly, including temporary ones

- Temporary electrical systems should be designed by someone competent, erected safely and tested and inspected. Test results should be requested and retained

- It should be possible to isolate all electrical systems in the case of emergency (e.g. fire)

Division Specific Issues

- This guidance applies across the ΒιΆΉΤΌΕΔ

Useful documents

-

[ΒιΆΉΤΌΕΔ Network only]

Recommended links

-

Risk Assessment This safety guideline lists the key measures for those wishing to complete a safety risk assessment

ΒιΆΉΤΌΕΔ electrical safety topics

-

Electrical safety homepage

A selection of guidance documents and general advice in relation to Electrical Safety in ΒιΆΉΤΌΕΔ premises, on productions and events. -

ΒιΆΉΤΌΕΔ policies for electrical safety

ΒιΆΉΤΌΕΔ policies detailing its overarching approach to the management of electrical safety. -

ΒιΆΉΤΌΕΔ electrical safety guidance documents

Summary of ΒιΆΉΤΌΕΔ electrical guidance (links within document titles) -

Electrical risk assessments and reporting of incidents

This section will help those who need to do a risk assessment where electricity is being used. It also gives guidance on reporting requirements for any electrically-related incident. -

Electrical safety in ΒιΆΉΤΌΕΔ Premises

General guidance on use of electricity and electrical equipment when working in ΒιΆΉΤΌΕΔ Premises. -

Electrical safety in Studios

A straightforward guide to electrical safety management in studios and similar locations. -

Safety of electrical equipment and appliances

Requirements for electrical safety of electrical equipment and appliances (βPAT testingβ). -

Electrical competency and Part P requirements

Guidance on what to look for when employing contractors or freelancers to do electrical work. -

Electrical safety requirements for Production Managers

Find out what you should know and what measures should be put in place for your production. -

Bringing your own equipment to work and contributorβs equipment

Basic guidance on the safe and appropriate use of personal electrical equipment whilst at work and requirements. -

Temporary electrical systems and BS 7909

Requirements for electrical safety management in accordance with BS 7909 for all temporary electrical systems. -

Small and Simple Temporary Electrical Systems

Guidance to help understand the requirements for simple temporary electrical systems such as interviews or photo shoots for example. -

Generators

Guidance on the use of temporary generators including the application of earth electrodes. -

Batteries

Guidance on the safe use and storage of batteries. -

Certificate in Temporary Electrical Systems

An electrical safety training course designed to ensure those working with electricity in temporary distribution systems on productions can comply with BS 7909 and the relevant parts of BS 7671. -

Electrical Principles Workshop to harmonise the approach to health and safety management on electricity across all areas.

Electrical Principles Workshop to harmonise the approach to health and safety management on electricity across all areas. -

External information and guidance on electrical safety

Links providing further information on all aspects of electrical safety, from external bodies (IET, HSE, Etc.) that ΒιΆΉΤΌΕΔ staff may find useful. Some guidance is required to be purchased. -

Health & safety Alerts and News

All the Health & Safety Alerts and News from the H&S Teams

More from SSR

-

Your platform to record accidents, risk assessments, assurance monitoring and inspections

-

Safety Equipment Stores

Just one number to call: 0844 800 8875 -

ΒιΆΉΤΌΕΔ Safety Guidelines

An A-Z of ΒιΆΉΤΌΕΔ's Health and Safety Guidelines -

Safety Advice Line: 0370 411 0464 Email: safety@bbc.co.uk

- A-Z of ΒιΆΉΤΌΕΔ Safety Guidelines

- Accident Reporting and Investigation

- ΒιΆΉΤΌΕΔ Health & Safety Policy

- Contractors (incl. vetted lists)

- Contributors

- Fire Safety

- Freelancers

- Independent Production Companies

- Risk Assessment

- Safety Alerts

- Safety Responsibilities

- Safety Training

- Sets & Premises Safety Guide

Events guidance - key links:

- Exhibitions

- General Guidance

- Indoor Location Recce Checklist

- Outdoor Location Recce Checklist

- Major Incidents & Emergency Planning

- Marketing and Promotional

- Noise Exposure

- Planning and Management

- Responsibilities

- Responsibilities Form

- Laser Lighting Effects

- Strobe Lighting

- Temporary Stages and Rostra

Health topics - key links:

- (ΒιΆΉΤΌΕΔ network only)

- Contributors Fitness to Participate

- Display Screen Equipment (DSE)

- (ΒιΆΉΤΌΕΔ network only)

- First Aid and Welfare on Location

- International Travel - Risks & Health

- Manual Handling

- Mental Health: ΒιΆΉΤΌΕΔpage

- (ΒιΆΉΤΌΕΔ network only)

- Personal Health and Wellbeing

- Pregnancy

- Psychological Trauma Support & Trauma Risk Management (TRiM)

- Tiredness and Fatigue

- Travel Health Contacts

ΒιΆΉΤΌΕΔ High Risk - key links:

- CBRN and Industrial Spills

- Covert Filming

- Crisis Management and Security Support

- Demonstrations, Protests and Crowds

- Disaster Coverage

- Door Stepping

- (ΒιΆΉΤΌΕΔ network only)

- (ΒιΆΉΤΌΕΔ network only)

- Public Order

- Safety Equipment Stores

ΒιΆΉΤΌΕΔ Journalism - key links:

ΒιΆΉΤΌΕΔ Productions - key links:

- Aerial Filming and Airfields

- Animals: Displaying and handling for performance

- Boats: Working on

- Children and Young People

- Driving

- Electrical Equipment and Systems

- First Aid and Welfare on Location

- Food Safety (Cooking and Catering)

- Remote Location Working

- Roads and Streets: Working by

- Security of Productions on Location

- Stunts

- Tiredness and Fatigue

- Unmanned Aerial Systems (UAS aka Drones)

- Vehicles: Recording in, from and around

- Working at Height: Mobile Elevating Work Platforms

- Working at Height: Tower Scaffolds

ΒιΆΉΤΌΕΔ Radio - key links:

- (ΒιΆΉΤΌΕΔ Network only)

ΒιΆΉΤΌΕΔ Security - key links:

ΒιΆΉΤΌΕΔ Sport - key links:

About this site

This site describes what the ΒιΆΉΤΌΕΔ does in relation to managing its health, safety and security risks and is intended for those who work directly for the ΒιΆΉΤΌΕΔ.

It is not intended to provide instruction or guidance on how third parties should manage their risks. The ΒιΆΉΤΌΕΔ cannot be held liable for how this information is interpreted or used by third parties, nor provide any assurance that adopting it would provide any measure of legal compliance. More information

Some links on this site are only accessible when connected to the ΒιΆΉΤΌΕΔ network