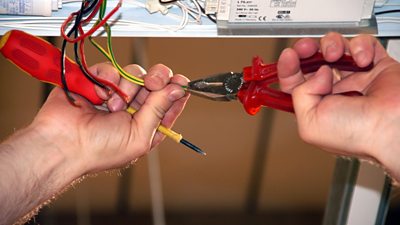

A significant number of electrically related injuries and fires in the workplace arise from poorly maintained equipment and so it is important that equipment is checked regularly. This process is often referred to as βPAT testingβ but the types of checks required are often misunderstood and the frequency of tests not carried out with real consideration of the actual risks. The ΒιΆΉΤΌΕΔ guidance takes into account current HSE and Institution of Engineering and Technology (IET) guidance and provides practical and pragmatic advice on managing electrical equipment.

Most common electrical hazards can be seen and do not require any particular electrical training or skills. Problems such as broken equipment, damaged cables or plugs/sockets are obvious and so the ΒιΆΉΤΌΕΔ guidance places a great reliance on the user-check being the primary line of defence.

Everyone uses electrical equipment, whether it is a mixing desk in a studio, a laptop power supply or kettle in the kitchen; everyone has duties to help keep equipment safe by doing simple checks before it is used. The ΒιΆΉΤΌΕΔ expects that all staff will ensure such user checks are carried out on the equipment that they use, whether or not it is equipment under their control. Examples of user checks are given in the documents on this page.

βBring your own deviceβ or BYOD is more commonplace with the advent of personal mobile phones and similar equipment although it is more common in productions where freelancers might bring their own cameras or similar equipment. See the page on Bringing your own equipment to work for more information on this.

Essentially any electrical equipment in the workplace should be maintained, whether owned by the ΒιΆΉΤΌΕΔ, hired or leased. Electrical inspection and testing may require co-ordination with the owner of the equipment to ensure that it is done safely and does not put the equipment at risk of damage.

The requirements apply to all electrical equipment, whether battery operated or mains-powered. The level of inspection and, if required, testing varies depending on what the equipment is.

What Can Go Wrong?

Death, injury or fires arising from:

- Damaged or broken equipment cases

- Chaffed, cut or other damage to electrical cables

- Damage to plugs and sockets such as bent pins, damaged cases, signs of overheating or exposed wires

- Inappropriate use of equipment (e.g. connecting a European style plug into a UK style socket)

Legal/ΒιΆΉΤΌΕΔ Requirements

- Both the Provision and Use of Work Equipment Regulations 1998 and the Electricity at Work Regulations 1989 (EAWR) require equipment in the workplace to be maintained.

- The ΒιΆΉΤΌΕΔ guidance on the electrical safety of equipment states the requirements for the frequency of inspection and testing and the levels of competency for those doing the checks.

- Information on the test methods and requirements for the visual inspection is available from the IET (See links).

- Equipment mounted in racks and bays such as servers or production equipment is subject to a different routine described in the ΒιΆΉΤΌΕΔ Guidance on rack and bay testing

- The also provide useful guidance including FAQs on portable appliance testing

- Employees must not use any electrical equipment (whether their own or not) if they suspect it of being damaged or dangerous. If safe to do so, disconnect it and take it out of service and report it as a near miss on MyRisks.

Division Specific Issues

- The ΒιΆΉΤΌΕΔ guidance on the electrical safety of portable appliances covers all areas of the ΒιΆΉΤΌΕΔ including studios, workplace and foreign bureaux and offices.

- Generally equipment taken by UK based staff and used abroad will be still be subject to the same requirements of this guidance. Where local equipment is sourced and used in foreign offices by local staff, the UK legal requirements will not apply. However it is the ΒιΆΉΤΌΕΔβs policy that the principles of this guidance should be applied to ensure the safety of staff in the ΒιΆΉΤΌΕΔβs employment.

- ΒιΆΉΤΌΕΔ Workplace is responsible for inspection and test for the fixed electrical supply and infrastructure in ΒιΆΉΤΌΕΔ buildings.

- Each division/department is responsible for its own electrical equipment and must have systems in place to ensure that appropriate checks are in operation.

- The facilities management teams can arrange for the inspection and testing of equipment that you plug into the building supply.

Useful documents

-

[ΒιΆΉΤΌΕΔ Network only] Revision 12. May 2023

-

[ΒιΆΉΤΌΕΔ network only] Revision 8. May 2023

-

[ΒιΆΉΤΌΕΔ network only]

ΒιΆΉΤΌΕΔ electrical safety topics

-

Electrical safety homepage

A selection of guidance documents and general advice in relation to Electrical Safety in ΒιΆΉΤΌΕΔ premises, on productions and events. -

ΒιΆΉΤΌΕΔ policies for electrical safety

ΒιΆΉΤΌΕΔ policies detailing its overarching approach to the management of electrical safety. -

ΒιΆΉΤΌΕΔ electrical safety guidance documents

Summary of ΒιΆΉΤΌΕΔ electrical guidance (links within document titles) -

Electrical risk assessments and reporting of incidents

This section will help those who need to do a risk assessment where electricity is being used. It also gives guidance on reporting requirements for any electrically-related incident. -

Electrical safety in ΒιΆΉΤΌΕΔ Premises

General guidance on use of electricity and electrical equipment when working in ΒιΆΉΤΌΕΔ Premises. -

Electrical safety in Studios

A straightforward guide to electrical safety management in studios and similar locations. -

Safety of electrical equipment and appliances

Requirements for electrical safety of electrical equipment and appliances (βPAT testingβ). -

Electrical competency and Part P requirements

Guidance on what to look for when employing contractors or freelancers to do electrical work. -

Electrical safety requirements for Production Managers

Find out what you should know and what measures should be put in place for your production. -

Bringing your own equipment to work and contributorβs equipment

Basic guidance on the safe and appropriate use of personal electrical equipment whilst at work and requirements. -

Temporary electrical systems and BS 7909

Requirements for electrical safety management in accordance with BS 7909 for all temporary electrical systems. -

Small and Simple Temporary Electrical Systems

Guidance to help understand the requirements for simple temporary electrical systems such as interviews or photo shoots for example. -

Generators

Guidance on the use of temporary generators including the application of earth electrodes. -

Batteries

Guidance on the safe use and storage of batteries. -

Certificate in Temporary Electrical Systems

An electrical safety training course designed to ensure those working with electricity in temporary distribution systems on productions can comply with BS 7909 and the relevant parts of BS 7671. -

Electrical Principles Workshop to harmonise the approach to health and safety management on electricity across all areas.

Electrical Principles Workshop to harmonise the approach to health and safety management on electricity across all areas. -

External information and guidance on electrical safety

Links providing further information on all aspects of electrical safety, from external bodies (IET, HSE, Etc.) that ΒιΆΉΤΌΕΔ staff may find useful. Some guidance is required to be purchased. -

Health & safety Alerts and News

All the Health & Safety Alerts and News from the H&S Teams

More from SSR

-

Your platform to record accidents, risk assessments, assurance monitoring and inspections

-

Safety Equipment Stores

Just one number to call: 020 3614 5155 -

ΒιΆΉΤΌΕΔ Safety Guidelines

An A-Z of ΒιΆΉΤΌΕΔ's Health and Safety Guidelines -

Safety Advice Line: 0370 411 0464 Email: safety@bbc.co.uk

- A-Z of ΒιΆΉΤΌΕΔ Safety Guidelines

- Accident Reporting and Investigation

- ΒιΆΉΤΌΕΔ Health & Safety Policy

- Contractors (incl. vetted lists)

- Contributors

- Fire Safety

- Freelancers

- Independent Production Companies

- Risk Assessment

- Safety Alerts

- Safety Responsibilities

- Safety Training

- Sets & Premises Safety Guide

Events guidance - key links:

- Exhibitions

- General Guidance

- Indoor Location Recce Checklist

- Outdoor Location Recce Checklist

- Major Incidents & Emergency Planning

- Marketing and Promotional

- Noise Exposure

- Planning and Management

- Responsibilities

- Responsibilities Form

- Laser Lighting Effects

- Strobe Lighting

- Temporary Stages and Rostra

Health topics - key links:

- (ΒιΆΉΤΌΕΔ network only)

- Contributors Fitness to Participate

- Display Screen Equipment (DSE)

- (ΒιΆΉΤΌΕΔ network only)

- First Aid and Welfare on Location

- International Travel - Risks & Health

- Manual Handling

- Mental Health: ΒιΆΉΤΌΕΔpage

- (ΒιΆΉΤΌΕΔ network only)

- Personal Health and Wellbeing

- Pregnancy

- Psychological Trauma Support & Trauma Risk Management (TRiM)

- Tiredness and Fatigue

- Travel Health Contacts

ΒιΆΉΤΌΕΔ High Risk - key links:

- CBRN and Industrial Spills

- Covert Filming

- Crisis Management and Security Support

- Demonstrations, Protests and Crowds

- Disaster Coverage

- Door Stepping

- (ΒιΆΉΤΌΕΔ network only)

- (ΒιΆΉΤΌΕΔ network only)

- Public Order

- Safety Equipment Stores

ΒιΆΉΤΌΕΔ Journalism - key links:

ΒιΆΉΤΌΕΔ Productions - key links:

- Aerial Filming and Airfields

- Animals: Displaying and handling for performance

- Boats: Working on

- Children and Young People

- Driving

- Electrical Equipment and Systems

- First Aid and Welfare on Location

- Food Safety (Cooking and Catering)

- Remote Location Working

- Roads and Streets: Working by

- Security of Productions on Location

- Stunts

- Tiredness and Fatigue

- Unmanned Aerial Systems (UAS aka Drones)

- Vehicles: Recording in, from and around

- Working at Height: Mobile Elevating Work Platforms

- Working at Height: Tower Scaffolds

ΒιΆΉΤΌΕΔ Radio - key links:

- (ΒιΆΉΤΌΕΔ Network only)

ΒιΆΉΤΌΕΔ Security - key links:

ΒιΆΉΤΌΕΔ Sport - key links:

About this site

This site describes what the ΒιΆΉΤΌΕΔ does in relation to managing its health, safety and security risks and is intended for those who work directly for the ΒιΆΉΤΌΕΔ.

It is not intended to provide instruction or guidance on how third parties should manage their risks. The ΒιΆΉΤΌΕΔ cannot be held liable for how this information is interpreted or used by third parties, nor provide any assurance that adopting it would provide any measure of legal compliance. More information

Some links on this site are only accessible when connected to the ΒιΆΉΤΌΕΔ network