Industrial production techniques

Using computer aided design (CAD) and computer aided manufacture (CAM) in a manufacturing setting

There are four terms used to describe the scale of production in relation to manufacturing a product:

- prototypeThe first working model of a design used for testing, development and evaluation. or one-off production

- batch productionWhere one group of identical products is made at the same time, before moving onto producing the next group.

- mass productionWhen the same product is manufactured many times.

- continuous productionA production method that leads to many of the same product being made, continuously.

Prototype and one-off production

Prototyping can be used for testing and in user trials. As well as this, bespokeMade as a one-off product that matches the client requirements exactly. specialist machines and vehicles can be made for a client using one-off production. Specialist workers and production aids are needed. This can produce high-quality and original objects, but they are often expensive to make and buy, and highly skilled workers are needed to produce them.

When testing a circuit, a breadboardA non-solder way to model electrical circuits. or stripboard can be used to ensure that the circuit functions correctly without more permanent soldering. If the circuit works after the prototype has been tested, it could be then possible to have the circuit made in larger quantities.

Batch production

Batch production is where many items of the same product are produced, such as mobile phones and TVs. A range of products can be made, particularly ones that are regularly changed, but time is lost when retoolingSet up a production line with different tools for a new task. and skilled workers are needed. When a product is made in a batch, it is often far cheaper per product than making just one.

Mass production

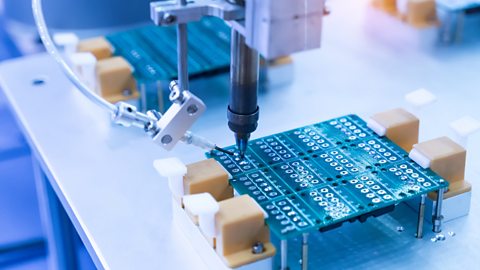

Mass-produced products are manufactured in large volumes, and are often made by automated machinery with assembly line A series of workers and machines in a factory by which a succession of similar items is progressively assembled. workers used to fit parts together or add standard components, such as switches. Examples of mass production for electronic and mechanical systems include radios, remote controls and cars. Products are kept low cost as a large number are made and bulk materials and components are cheaper to buy. There is, however, a large cost in setting up such an assembly line.

Continuous production

Continuous production takes place 24 hours a day, 7 days a week and, in some cases, 365 days a year. It can produce huge volumes of a product at a low cost, such as circuit board A copper sheet used to attach electrical components. or light-emitting diode (LED)Light-emitting diodes (LEDs) glow when current passes through them., but it is limited to a small range of products, and as with mass production it is expensive to set up.

Just in time (JIT)

just in time (JIT) manufacturingMaterials or parts are delivered just before they are needed. is triggered by a customer order. The correct amounts of materials are ordered in to cover the order, and these arrive just as they are needed by production. This saves money on storage, reduces waste and ensures there is no money wasted producing stock that will remain unsold. There are disadvantages to the system in that, if any part of the product cannot be sourced, clientIn business, a client is a person or organisation that wants a product manufactured, eg a retailer. have to wait for their order to be produced.

Using jigs within production

To help with the precise production of components and products, jigA tool used to aid the repetition of a process and/or to hold a work in place. are made. When many components are needed to be made identically, it can be very time-consuming without a jig. A jig can:

- secure the component whilst it is being machined or assembled accurately

- ensure all components are identical to the previous one

- save time and reduce human error

CAD in electronics

computer aided design (CAD)The process of creating a 2D or 3D design using computer software. has enabled electronics to increase in complexity:

- printed circuit boards (PCBs) and microprocessors can be produced to the tiniest of scales

- simulationsA model that produces an output, either visual or physical, as it runs. of circuit boards designed can be viewed

- systems can be tested digitally before manufacturing takes place

- it can save time and money

- inputs and outputs can be tested through the CAD software, replacing the need for a physical model2D or 3D representation of a product used to test before manufacture. Examples include sketches, CAD designs, virtual products, styrofoam models and prototypes.

CAM in electronics

computer aided manufacture (CAM)The manufacture of a part or product from a computer aided design (CAD) using computer-controlled machinery, such as a 3D printer. utilises sophisticated machinery and reads information from CAD software files. CAM machines can then accurately perform different automatedTurning a set of manual steps into an electronic operation that requires no human input. functions from the data, such as:

- drill holes

- computer numerical controlled (CNC) route copper tracks

- perform soldering

- assemble circuits