Casing electronic systems

casing A removable outer layer of a product. for electronic products often need to protect against moisture. There are many manufacturing processes available, which are chosen based on the design, the materials being used and the amount of products being made. Plastics are most commonly used with electronics as they:

- protect the components and the user

- insulate well

- are lightweight

- produce less waste than other materials

- are less expensive than other materials

Injection moulding

injection mouldingMolten material forced into a mould. is the most common process used in the production of electronic casings for a variety of reasons:

- it is an automated process

- it is fast

- it uses a wide variety of plastic materials (available in many colours)

- it can achieve complex shapes

- it leaves a good surface finish

The moulds are initially expensive to produce and are costly to change; however, once set up, mass production is possible.

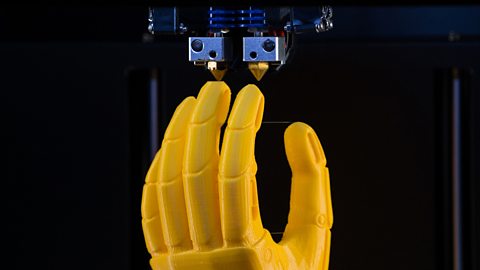

3D printing

3D printing A method of adding material in layers to build a solid form. is used in a variety of ways, such as in creating prosthetics, as it enables the designer to produce complex shapes without using a mould. Acrylonitrile butadiene styrene (ABS) plastic is commonly used with 3D printing as it is waterproof, wear resistant and available in many colours, although it can often warp on the 3D print bed. polylactic acid (PLA)A biodegradable thermoplastic from renewable resources, such as corn starch. is an easier material to print with as it melts at a lower temperature.

3D printing can also be utilised in the production of casings for electronic systems as they can be designed to encase the product perfectly.

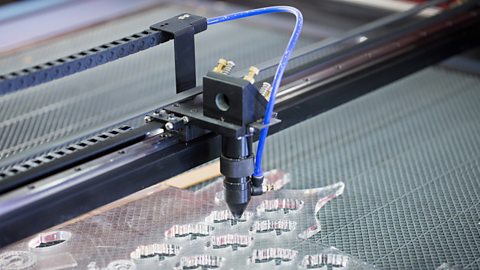

Laser cutting

laser cutterA machine that uses a laser beam to vaporise material and cut out shapes very accurately. can cut and engrave a variety of materials, and can be used to create suitable casings for electronic products.

Image caption, A laser cutter

Image caption, A laser engraver

1 of 2